Twin Screw Puff Snack Processing Line

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Twin Screw Puff Snack Processing Line

1 Introduction

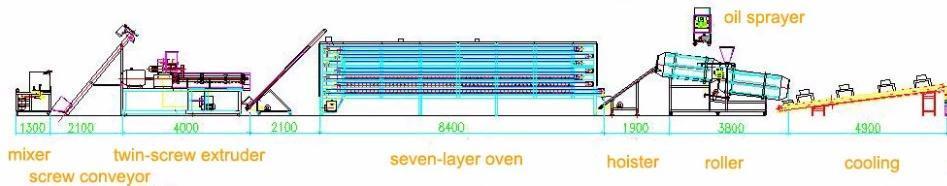

Fully automatic puffed snack production line, this is a fully automatic snack production line including a variety of processes, which can produce a variety of puffed snacks. It includes mixing, puffing, drying, seasoning, cooling and other steps. Snacks of different sizes and shapes can be obtained simply by changing the cut-off part of the extruder.

2 Production Video

3 Machine Display

4 Samples

5 Technical Parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

100-150kg/h | 120kw | 96kw | 26*3*2.2m | |

DSE65F Puff Snack Production Line | 100-150kg/h | 124kw | 100kw | 26*3*2.2m |

DSE70 Puff Snack Production Line | 200-250kg/h | 164kw | 132kw | 28*3*2.2m |

DSE70F Puff Snack Production Line | 200-250kg/h | 130kw | 104kw | 26*3*2.2m |

DSE85 Puff Snack Production Line | 300-500kg/h | 270kw | 216kw | 32*3*2.2m |

6 Flow Chart

Mixer→Screw Conveyor→Extruder→Air Conveyor→Dryer→Hoister→Flavoring System→Cooling Conveyor

7 Product Advantage

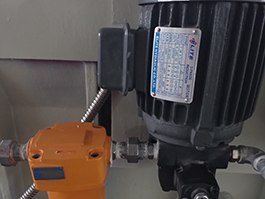

1.Adopt siemens foremost motor, delta inverter, schneider omron abb electrical components, the world's well-known manufacturers, secure, dependable and durable, can efficaciously manage the motor speed in line with the state of the product, lessen intake.

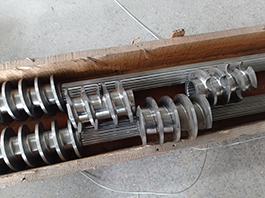

2. The screw cloth is excessive-pace alloy metallic, carburized, with hardness as much as hrc fifty five-65, high put on resistance, high hardness, right longevity, elective 38crmoal, 12crmov, w6mo5cr4v2 cloth, lengthy service existence. some fashions are equipped with a mixture screw, which has wider applicability of uncooked substances. the screw mixture method can be adjusted in line with one-of-a-kind products, and one gadget can be used for more than one functions.

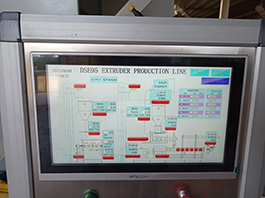

3.The main motor, rotary reducing motor and feeding motor are all controlled by means of frequency conversion, which could realise tender begin and efficiently shield the motor, and can adjust the velocity in keeping with the product popularity to produce better high-quality merchandise; equipped with p.c touch display screen manage machine, gadget temperature and the rate adjustment is extra digital and the control is more precise.

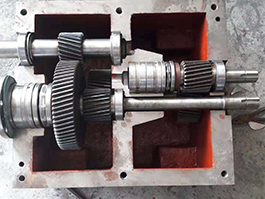

4.Using a brand new kind of field, the field material QT400, top stability. gear material 20CrNiMoA, carburizing and quenching, hardness hrc58-62, high precision, low noise, long service lifestyles; the use of jap nsk, skf bearings, high precision, long life, solid overall performance; oil pump motor, forced internal move lubrication; condenser, decrease the floor temperature of gears and bearings increases the service lifestyles; the filter cleans the impurities in the oil, improves the lubrication impact and prolongs the provider life.

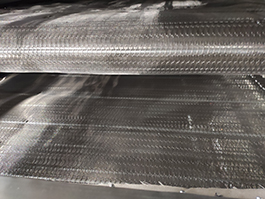

5.In line with the real scenario, distinctive energy assets, electricity, fuel oil, gas, steam may be used to save manufacturing costs; geared up with circulating enthusiasts and dehumidification enthusiasts to promote warmness movement, do away with water vapor, and improve drying performance; 304 stainless steel mesh material and mesh are used. belt to ensure product fine; adjustable going for walks speed, adjust drying time in keeping with different products, high efficiency.

Send your message to us

Related News

Pet Fair Asia 2025 We Are Coming

2025-08-08

Appetite Attractants in Pet Food

2025-06-21

Submitted successfully

We will contact you as soon as possible

Close