Explore Fried Food Production Line

Explore Fried Food Production Line

As the demand for snack foods grows, the market for fried foods continues to expand, driving the upgrade of related equipment. Fried food production lines have made significant progress in automation and intelligence, improving production efficiency and product quality.

1. Final sample picture

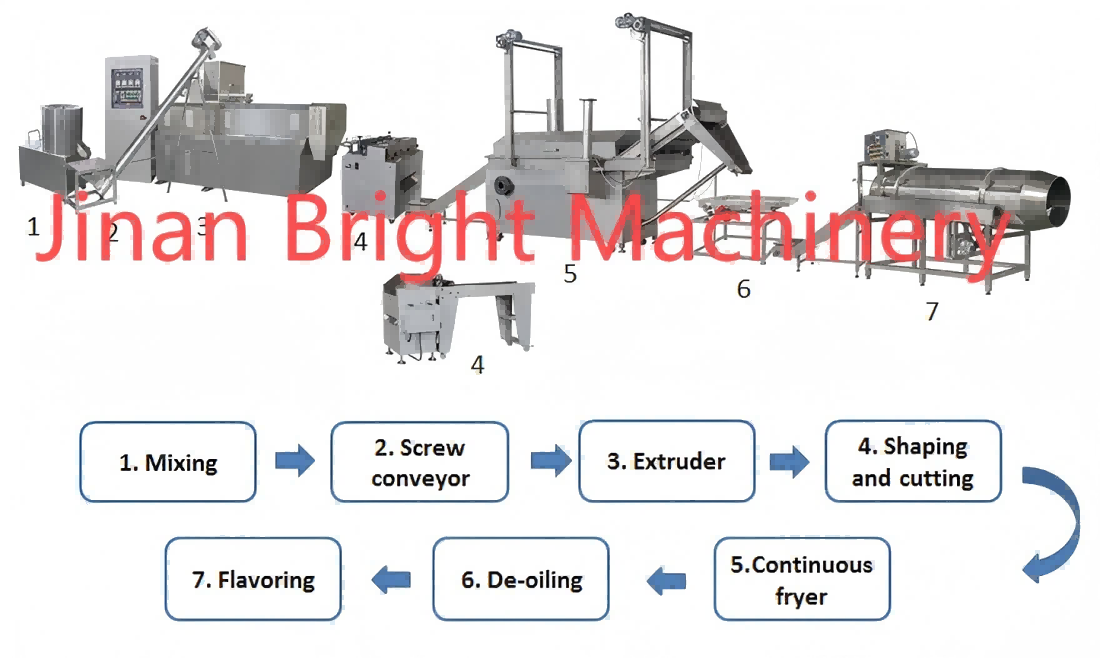

2. Production process

1. Raw material preparation

Main raw material: wheat flour

2. Mixing

Mixing: Add wheat flour and a certain proportion of water to the mixer and mix evenly.

3. Extrusion molding

Extruder: Feed the prepared raw materials into a twin-screw extruder for extrusion molding under high temperature and high pressure.

Cut-off machine cuts: Extrudes the unique shape of fried food (such as triangle or long strip) through a specific die.

4. Frying

The fryer adopts a double-layer mesh belt structure and direct heating. Due to the large heat demand of the feed port, a heater is installed at the feed port and an oil injection port is installed at the front end. At the same time, a paddle stirring device is provided, which has a certain stirring and pushing effect on the materials entering the fryer to prevent the materials from sticking to each other. This structural system has a small oil capacity and a fast turnover rate of frying oil, which is conducive to improving the quality of frying oil.

5. De-oiling

Remove excess oil from the product surface through a vibrating de-oiling machine

6. Seasoning

Seasoning equipment: Use a drum seasoning machine

Seasoning process: Spray or coat the fried food evenly with seasoning powder (such as cheese, barbecue, tomato, etc.).

7. Cooling

Cooling: Prevent water vapor from being generated after packaging.

8. Packaging

Automatic packaging machine: Pack the cooled product according to specifications.

3.Key technologies and equipment

1. Twin-screw extruder: core equipment that determines the puffing effect and shape.

2. Intelligent control system: Real-time monitoring of temperature, pressure, and other parameters to ensure stable product quality.

Full mixing: All raw materials enter the mixer for full mixing to ensure uniform mixing, so that the dog can get balanced nutrition in every bite.

Through the above process, every step of fried food from raw materials to finished products is strictly controlled and optimized to ensure that the product tastes crispy, has a unique flavor, and meets modern health and environmental protection needs.