Kurkure Food Extruder Automatic Line

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Kurkure Food Extruder Automatic Line

1.Introduction

Cheeto Kurkure is a special puffed and extruded food with a crisp texture. Cheetos can be fried or baked for flavor. Cheetos are loved by consumers for their delicious taste and crisp texture.Corn flour or grits are mixed with a certain proportion of water and put into cheeto single screw extruder. Squeezed and kneaded by the extruder's two turntables, the meal forms irregular, twisted shapes, which are then cut to the desired length by a cutter.

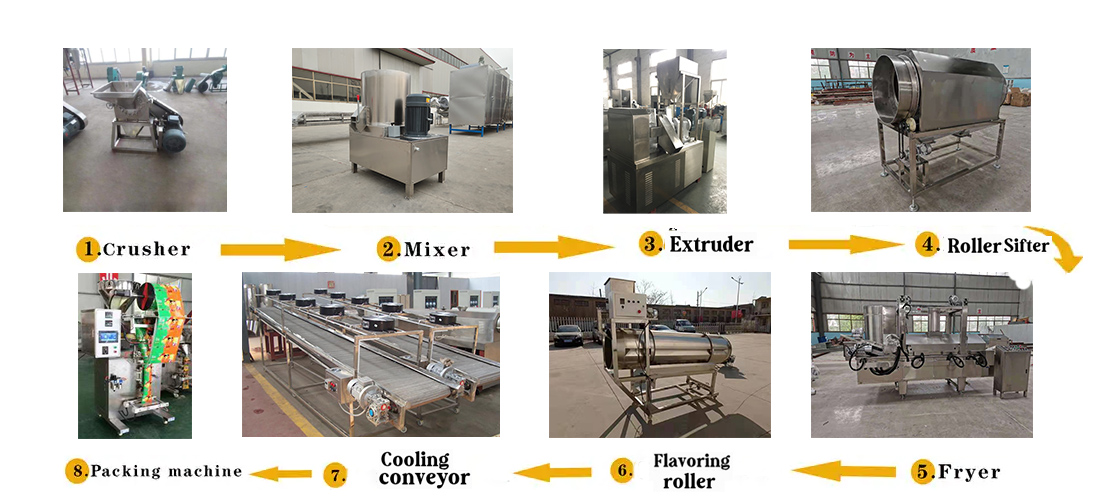

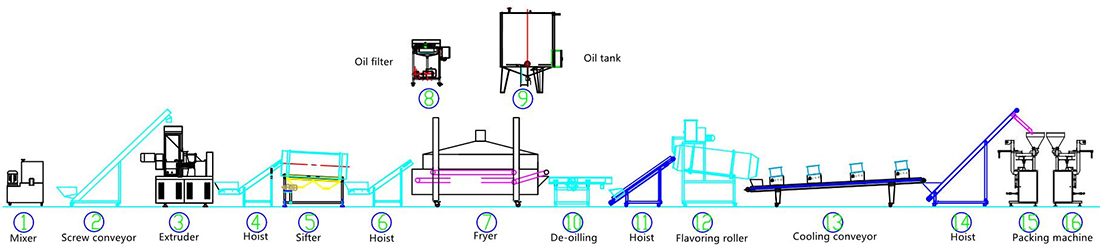

Frying type: ①Flour mixing machine→②Screw conveyor→③Rotary head extruder→④Elevator→⑤Separation cylinder→⑥Vibrating feeder→⑦Continuous fryer→⑧Vibration deoiling machine→⑨Seasoning line

2.Production Video

3.Machine Display

4.Samples

5.Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

SSE-76-1 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

SSE-76-2 production line | 100 | 70-80 | 150-200 kg/h | 21000*1500*3000 |

6.Flow Chart

Mixer→Screw conveyor→Extruder→Hoist→Roller screen→Hoistr→Fryer→De-oilling machine→Hoist→Flavoring roller→Cooling conveyor→Hoist→Packing machine

7.Product Advantages

1. Cheetos Kurkure products come in two different types, the first is baked and the second is fried. Different cocoa lines can be selected according to the local market. Both ovens and fryers can use different energy sources for drying, such as electricity, oil, gas, etc

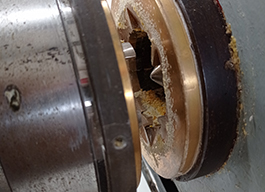

2. The latest rubbing and squeezing technology makes the product crisp and delicious,guarantee the product quality,uses bronze cutting pan to make the cheetos shape,high pressure and high temperature to have a good cure effect.

3. Exquisitely designed and precise control system,to adopt different material and make sure get the demanded puffing effect,the feeding and cutting motor frequency can be conreolled by the inverter,adjust according to material and final product.

4. The key parts are made of brass, which has good abrasion resistance,promise long service life,screw material 38CrMoAl,HRC 58-62,service life 1.5-2 years.

5. Food and material contact part is made by stainless steel 304 and food grade PVC,promise the food safety,the feeding silo and outlet are made by stainless steel 304,the silo with inspection window to check the material if need to feed or stop feeding.

Send your message to us

Related News

Pet Fair Asia 2025 We Are Coming

2025-08-08

Appetite Attractants in Pet Food

2025-06-21

Submitted successfully

We will contact you as soon as possible

Close