Macaroni Production Line

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Macaroni Production Line

1.Introduction

Single-screw pasta macaroni processing line adopts the semolina,wheat flour, corn starch and potato starch as the raw material then form a kind of leisure food after extruding, slaking, forming and drying. Various shapes of pasta macaroni can be made by this line just changing the dies of extruder. The production line is equipped with world-renowned electrical parts and frequency converters, which are safe and reliable, and the water cooling system has accurate temperature control

2.Production Video

3.Machine display

4.Samples

5.Technical parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

SSE100 Pasta Production Line | 100-150kg/h | 134kw | 108kw | 27*3*2.5m |

DSE75F Pasta Production Line | 200-300kg/h | 200kw | 160kw | 30*3*2.5m |

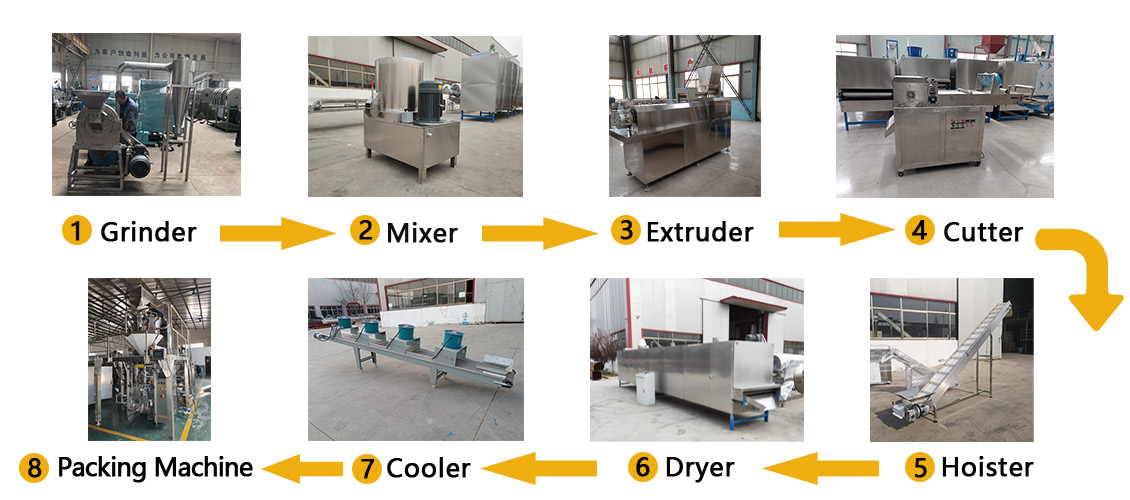

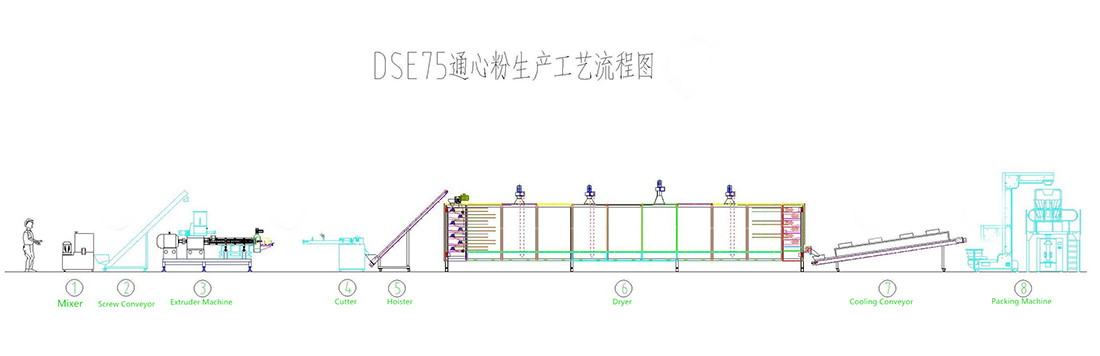

6.Flow chart

Mixer→Screw Conveyor→Extruder→Cutter→Hoister→Dryer→Cooling Conveyor→Packing Machine

7.Product Advantages

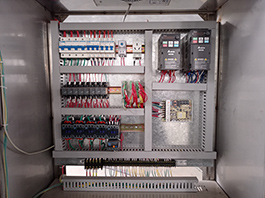

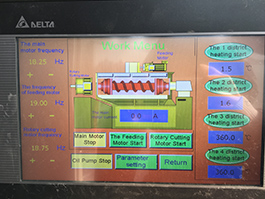

1. The extruder adopts advanced frequency converter speed regulation technology, so that the equipment has strong power, more stable operation, more electricity saving. Common brands, Siemens motor, Delta inverter, Schneider or Omron electrical parts

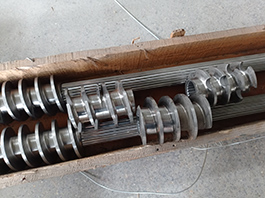

2. The screw adopts alloy steel nitriding treatment, longer life of the screw, individual equipment adopts building block combination structure, can be arbitrarily combined according to different needs

3. Visual automatic temperature control system, to make the temperature control more intuitive, more accurate parameters. Optional Delta or Siemens brand PLC control system

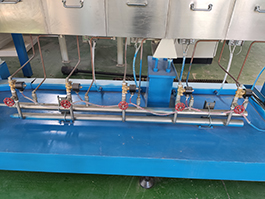

4. Equipped with water cooling system, more accurate temperature control, better product molding

5. New high strength Gear box, made of QT400, aging treatment and good stability; oil filter and oil cooler to extend the life of the gearbox

Send your message to us

Related News

Pet Fair Asia 2025 We Are Coming

2025-08-08

Appetite Attractants in Pet Food

2025-06-21

Submitted successfully

We will contact you as soon as possible

Close