TSP Soy Protein Making Machine

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

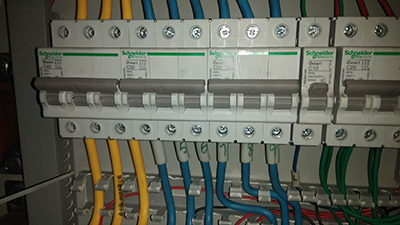

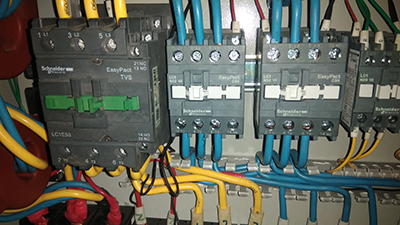

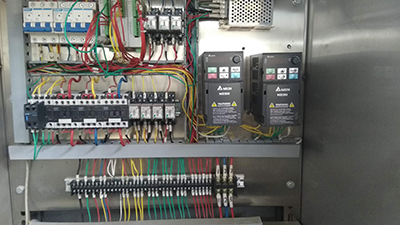

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

TSP Soy Protein Making Machine

1.Introduction

TVP/TSP is a fibrous plant protein with a texture similar to muscle fiber formed by the production and processing of plant protein with special technology.

TVP/TSP can be added to meat products instead of chicken and protein isolate. It can not only increase the protein content of meat products, but also absorb excess fat, making it non-greasy and non-greasy and more meaty, achieving economical purpose.

Raw materials are mostly processed soybean products, such as defatted soybean meal, protein concentrate, protein isolate, gluten, etc.

2.Production video

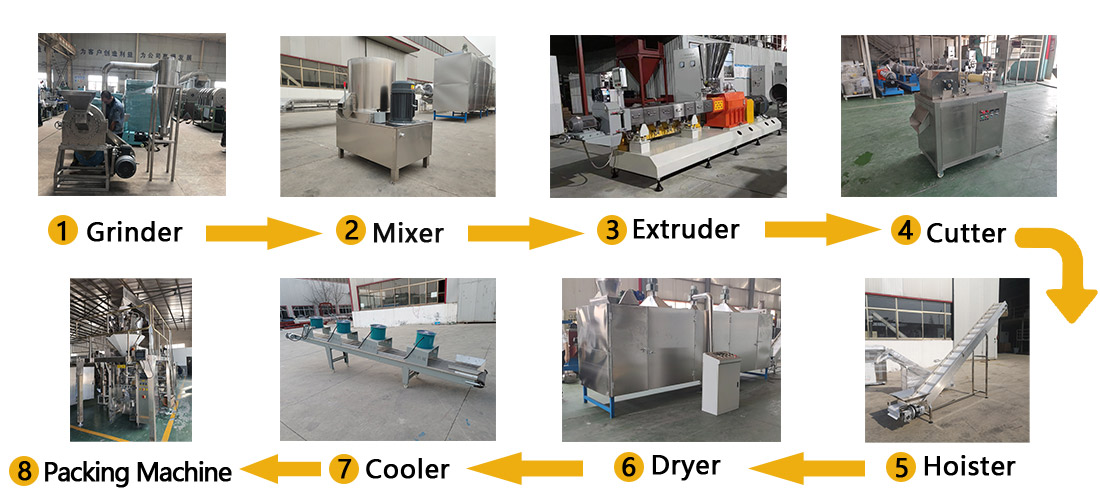

3.Machine display

4.Samples

5.Technical parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

DSE65 Soy Protein Production Line | 200-250kg/h | 116kw | 93kw | 20*3*2.2m |

DSE65F Soy Protein Production Line | 200-300kg/h | 134kw | 107kw | 24*3*2.2m |

DSE77 Soy Protein Production Line | 300-400kg/h | 158kw | 126kw | 26*3*2.2m |

DSE75F Soy Protein Production Line | 300-500kg/h | 178kw | 143kw | 30*3*2.2m |

DSE85 Soy Protein Production Line | 400-500kg/h | 210kw | 168kw | 36*3*2.2m |

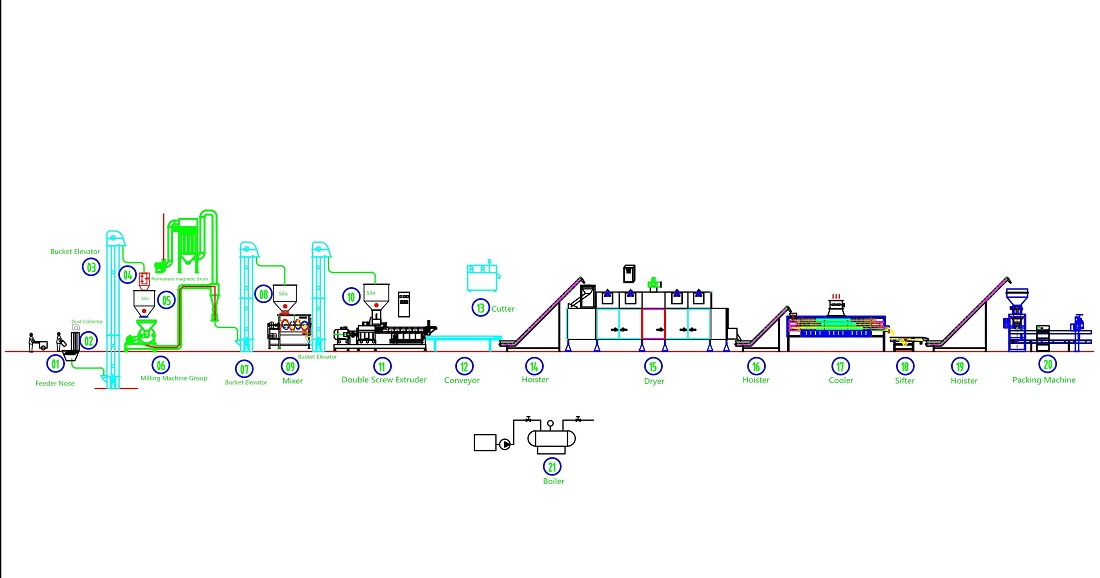

6.Flow chart

Feeder Nose→Dust Collector→Bucket Elevator→Permanent Magnetic Drum→Bucket Elevator→Silo→Milling Machine Group→Bucket Elevator→Silo→Mixer→Bucket Elevator→Silo→Double Screw Extruder→Conveyor→Cutter→Hoister→Dryer→Hoister→Cooler→Sifter→Hoister→Packing Machine

7.Product advantages

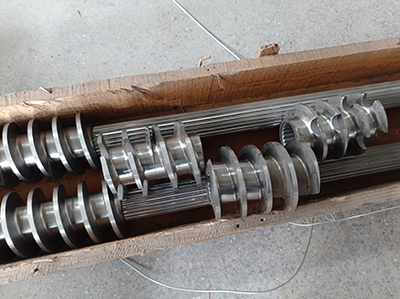

The twin-screw extruder for TVP/TSP soya protein is a continuous, high-temperature, high-pressure, and short-term sterilization process. It is a processing method that integrates multiple processing procedures. Compared with the traditional production process, the twin-screw extruder produces Soy protein has the following characteristics:

1. It can modify protein molecules to form a new cross-linked and layered fiber structure, and has good rehydration and oil retention performance; it can decompose protein, which is easy to digest and absorb, and its nutritional value is improved.

2. Short production process, low production cost, high output, energy saving and high efficiency, simple equipment supporting, small footprint, convenient operation, no sewage and waste gas generation, environmental protection and low carbon.

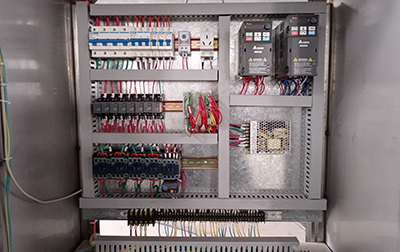

3. Optional Delta or Siemens brand PLC control system, more accurate and convenient

4. Modular screw with building block structure effectively reduces replacement cost. Screw material is 38CrMoV or 12CrMoV, strong and durable

5. Famous brand electrical parts, safe and reliable, NSK or SKF brand bearing, long working life, low noise

Send your message to us

Related News

Pet Fair Asia 2025 We Are Coming

2025-08-08

Appetite Attractants in Pet Food

2025-06-21

Submitted successfully

We will contact you as soon as possible

Close