Soya Bean Protein Making Extruder

Soya bean protein making extruder, which is a continuous, high-temperature, high-pressure, short-time sterilization process. It is a processing technique that integrates more than one processing procedures. Soybean pulled protein has the following characteristics:

1. It can alter protein molecules to shape new cross-linked and layered fiber structures, with precise rehydration and oil retention properties; it can decompose proteins, facilitate digestion and absorption, and enhance nutritional value.

2. Short-term excessive temperature and excessive stress eliminates a number damaging elements (trypsin, urease, saponin and hemagglutinin, etc.) contained in soybeans, and can take away beany odor and flatulence.

3. The manufacturing technique is short, the manufacturing price is low, the time and space output is high, electricity saving and excessive efficiency, the tools is simple, the region is small, the operation is convenient, no sewage and waste fuel are generated, and it is green, environmentally pleasant and low-carbon.

4. Soya bean protein making extruder is easy and convenient to alternate the country and structure of the product, and the merchandise are greater diverse.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

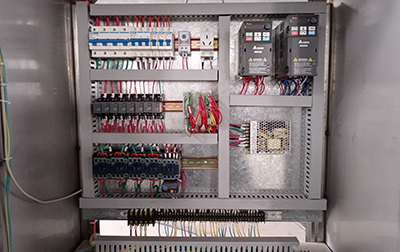

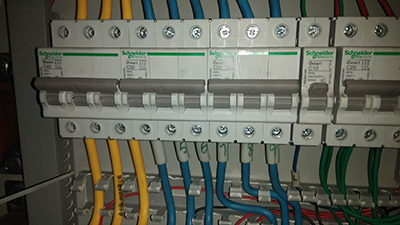

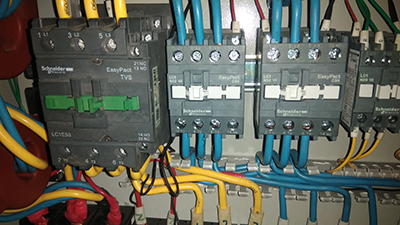

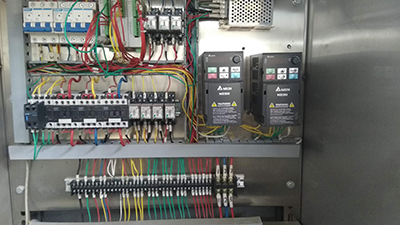

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Soya Bean Protein Making Extruder

1.Introduction

HMMA on the different hand is characterised with the aid of its excessive percentage of moisture. It normally consists of 50-80% of water which is about the identical as lean meat. Therefore it is used for many ready-to-eat meat dishes.

Both TVP and HMMA are manufactured by soya bean protein making extruder. When the soften discharges from the extruder, the set-up drastically differs from one another. While TVP is launched and without delay reduce at the nozzle plate, HMMA requires a one of a kind cooling die. In the cooling die the fabric is cooled down whilst being compelled into a laminar flow. This way, a meat-like shape is created.

Originally, the set-up required two extraordinary systems. Since Soya bean protein making extruder require extra flexibility, we have developed an adapter answer to shortly trade the identical base machine from TVP to HMMA and vice versa. As a result, meals producers can now use the very identical meals extruder for each applications.

2.Production video

3.Machine display

4.Samples

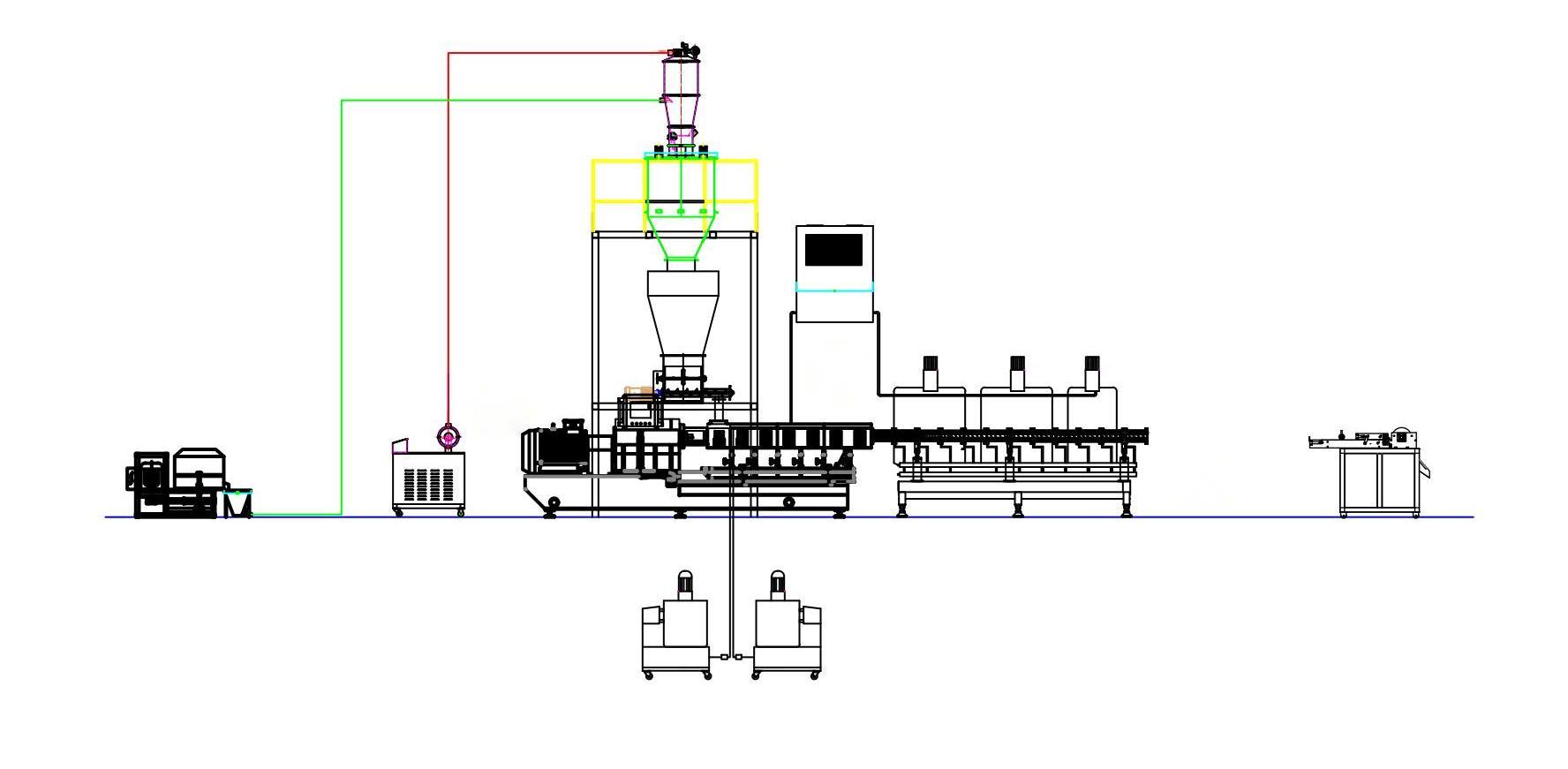

5.Technical parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

DSE65F Soy Protein Production Line | 200-300kg/h | 134kw | 107kw | 24*3*2.2m |

DSE75F Soy Protein Production Line | 300-500kg/h | 178kw | 143kw | 30*3*2.2m |

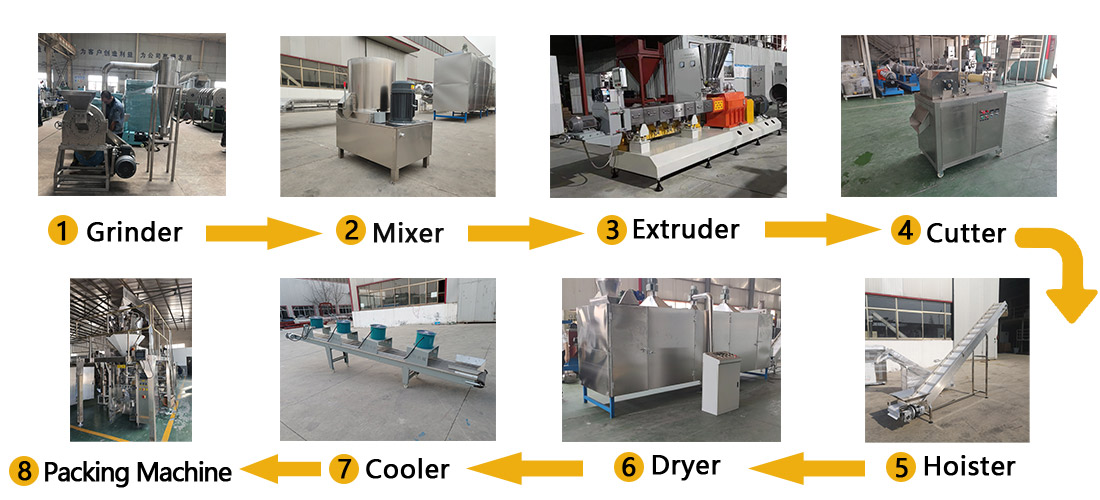

6.Flow chart

Mixer→Air Conveyor→Silo→Double Screw Extruder→Cooling Die→Cutter→Cooler

7.Product advantages

Vegan and Vegetarian meat substitute products have been gaining popularity in the last years. These meat analogues are based on plant-based proteins and come in various shapes and sizes, Soya bean protein making extruder produces soy protein has the following characteristics:

1. Soya bean protein making extruder can modify protein molecules to form a new cross-linked and layered fiber structure, and has good rehydration and oil retention performance; Soya bean protein making extruder can decompose protein, which is easy to digest and absorb, and its nutritional value is improved.

2. Short production process, low production cost, high output, energy saving and high efficiency, simple equipment supporting, small footprint, convenient operation, no sewage and waste gas generation, environmental protection and low carbon.

3. Optional Delta or Siemens brand PLC control system, more accurate and convenient

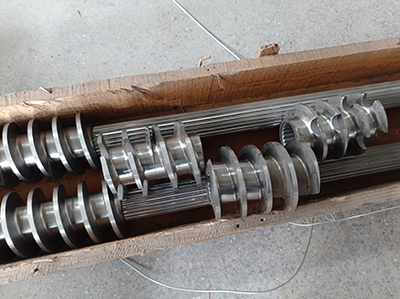

4. Modular screw with building block structure effectively reduces replacement cost. Screw material is 38CrMoV or 12CrMoV, strong and durable

5. Soya bean protein making extruder have famous brand electrical parts, safe and reliable, NSK or SKF brand bearing, long working life, low noise

Send your message to us

Related News

Pet Fair Asia 2025 We Are Coming

2025-08-08

Appetite Attractants in Pet Food

2025-06-21

Submitted successfully

We will contact you as soon as possible

Close