The main factors affecting the final moisture content of feed products are: the moisture content of the feed material itself, the moisture change in the crushing stage, the amount of liquid added in the mixing stage, the moisture content of the steam, the level of tempering, the die hole size and…

2022/12/13 09:34

First of all, we take the production of aquatic feed as an example, according to the material and purpose of the expansion from the structure of the single screw extruder and twin screw extruder,In general:--- Single screw extruder: suitable for processing all kinds of raw materials and common…

2022/12/10 18:08

Expanded/Puffing Feed Introduction:The expanded feed is a kind of puffy and porous feed formed by expanding the feed. Double screw fish feed extruder extruding is a processing technology that depressurizes the material after high temperature and high pressure treatment and changes some physical and…

2022/11/30 09:41

1.5-2T/h fish feed production line is loaded and shipped. Recently, we have received many orders for high-capacity production lines, and the next few days will be the peak shipment period for high capacity production lines. Welcome new and old friends to consult our equipment, we will serve you…

2022/11/27 16:02

1. Undertake siemens critical motor, delta inverter, schneider omron abb electric powered components, the world's pinnacle manufacturers, environment friendly and steady operation, reliable great, lengthy lasting, international add-ons, can be at as soon as bought locally, successfully lowering …

2022/11/14 16:13

First: The surface of the particle is uneven1. It has a great impact on the appearance of the finished product. In addition, it is easy to collapse when put into water, and the utilization rate is low. The main reasons are:(1) The raw materials were crushed too coarse, and failed to fully mature…

2022/11/09 13:27

What's the Difference Between Single Screw Extruder and Double Screw Extruder for Cat Dog Fish Feed?

The extruder is mainly composed of a barrel and a screw rotating in the extruder barrel, there are single screw extruder and twin screw extruder two categories. In the process of extrusion processing, the material from the feeding port into the die cavity, driven forward by the screw conveyor, by…

2022/11/08 10:11

1. The surface of the particles is uneven(1). It has a great impact on the appearance of the finished product, and it is easy to collapse when put into water, and the utilization rate is low. The main reasons are:A. The raw materials are too coarsely pulverized. During the quenching and tempering…

2022/10/31 11:45

The automated fried snack manufacturing line makes powdered uncooked substances which includes corn flour into fried snack through the method of blending,extruding,frying,flavoring and cooling. the same production line can produce fried snacks of numerous patterns and sizes. at the equal time, the…

2022/10/11 11:44

Nutritional powder is commonly known as enteral nutrition preparation. Its main function is to supplement the energy needed by the body. Nutritional powder changes its shape according to daily food and is refined into powder for patients or specific people to take. For special patients who cannot…

2022/10/11 11:34

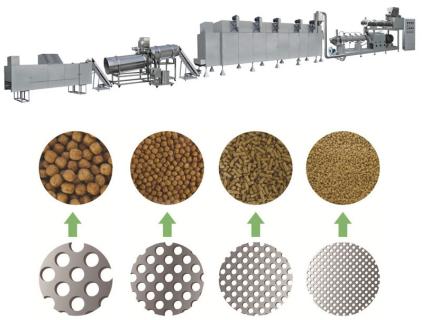

Using floating fish feed machinery to provide aquatic extruded feed now not handiest saves a lot of time, but additionally improves hard work productivity. floating fish feed machinery can produce distinctive length of fish feed.breeders can calculate the quantity of bait to be fed according to the…

2022/10/11 11:27

Recently, our company completed the installation and testing of 300 kg per hour nutrient-enriched fortified rice production line, and the machine is running well. The machine model is a new 75 square barrel extruder, equipped with built-in water cooling system, oil filtration and oil cooling system…

2022/09/20 15:47

Submitted successfully

We will contact you as soon as possible

Close